Future Classics: Sustainable Furniture Design

Future Classics: Sustainable Furniture Design

Each year, Earth Overshoot Day, the day when humanity has used more from nature than the Earth can regenerate in a year, grows closer. In light of this, sustainable design, in all sectors, remains a major focus.

The sheer scale of the world’s furniture production is astonishing, yet so often overlooked in light of our consumer culture. Despite being a necessity, much of the furniture we purchase comes with a hefty price on natural resources. Plastic waste, hazardous chemicals, and deforestation all result from furniture production. And with the global sum of furniture sales totalling an astounding USD $18,000 every second (equivalent to the total economic output of Sweden) the need for sustainable furniture design is becoming ever more pressing.

This has led to a wave of innovative designers and manufacturers creating sustainable furniture that is shining a light on how the furniture industry can shift towards more sustainable production and consumption practices. Driven by the vision of a more future-oriented world, collectible furniture designers are creating pieces that will become “future classics”. Not simply because they will last decades, but because they represent an ethical and stylistic milestone in the history of furniture design.

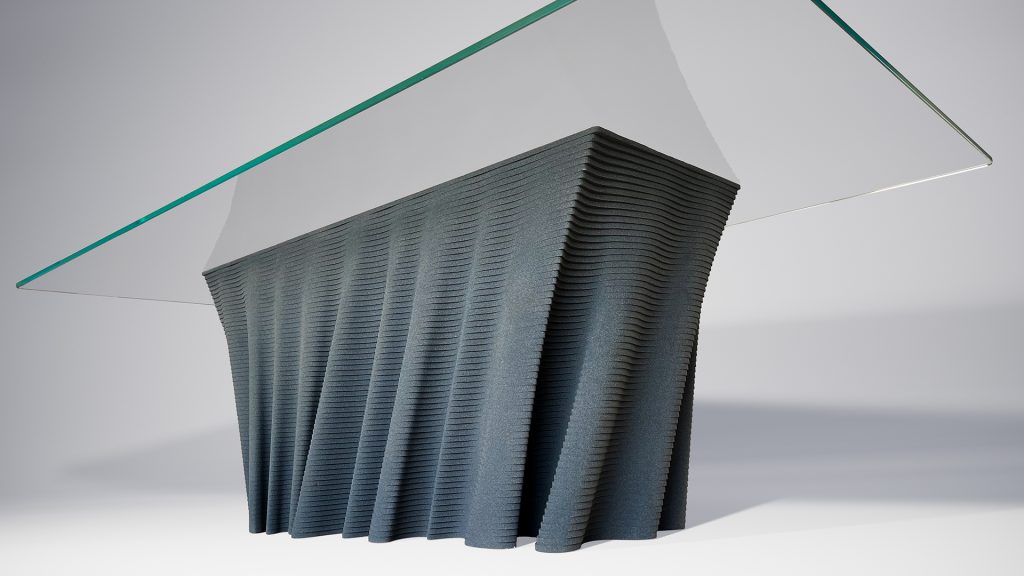

An evolution in furniture design: The Dune Coffee Table

At Duffy London, we have embraced the challenge of creating furniture in a sustainable and future-friendly way. Utilising sustainable production methods to bring to life the vision of designer and founder Christopher Duffy, the Dune Coffee Table represents a thought-provoking, visually arresting statement piece, that truly captivates the essence of the desert with its incredible fluidity and movement.

Inspired by the wave-like patterns of sweeping sand dunes, the table embodies a raw, yet refined feel of organic minimalism. Constructed with carefully chosen materials, including black or natural sand, and paired with a thick glass tabletop to give a sense of grandeur, the finished piece is a stunning combination of sculptural design and sustainable practices.

Collectible design that blows apart the brief

Using a 3D printed sand approach, creating the table uses fewer raw materials, significantly reducing both energy and material waste when compared to conventional manufacturing processes.

With many of the free-flowing twists and distortions of the table base proving difficult to achieve in other manufacturing processes, founder Christopher Duffy and the design team required natural materials as well as a process that could match the artistic, concept-driven designs.

By choosing to partner with the German manufacturer Sandhelden, our team was able to take advantage of their specialized, 3D printed sand production process. Speaking about his experience working with Sandhelden, Christopher Duffy said “Our designs can be twisted on their heads, scaled up, and formed as larger furniture pieces and sculptural forms. It looks alluring, it captivates, and it feels both weighty and tactile to the touch. We are already starting to explore future concepts and special editions, so this is only the beginning…”

Minimising environmental impact

To manufacture furniture using 3-D printing techniques, binder jetting is employed. This process involves depositing a binding agent onto the surface of thin layers of powdered material. Within the Dune Coffee Table creation process, quartz sand from Bavaria is used. As its grain shape is edgier, it allows the binder to pass smoothly through every layer of sand. This makes the entire process up to 40% more economical than other 3D printing processes.

Not only that, but Sandhelden successfully manages to create a truly sustainable manufacturing model with their binders composed of recycled materials such as corn husks, rice hulls, sugar cane, as well as other biomaterials. This significant effort in sustainability is creating a strong vision for creating furniture of the future.

“We are passionate about discovering and working with new mediums, so are thrilled to reveal our new DUNE Table. Working with Sandhelden, we’ve been able to understand the beauty and versatility of 3D printing with sand.”

-Christopher Duffy, Founder of Duffy London.

Creating the future of eco-friendly design

Sandhelden’s revolutionary process is not just a sustainable one, but it also allows our design team to create with a level of freedom that has been previously unheard of. Creating a piece of furniture with this level of sculptural detail meant that the team could push boundaries of design.

By 3D printing with sand, we gain the flexibility and versatility to create a seamless design that is also low-waste and sustainable. With this, we can keep producing the highest quality pieces that make a conscious effort to reduce our environmental impact.

“I love all aspects of innovation in design and manufacturing, and this is no different. We all need to be challenged, so by 3D printing in actual quartz sand, we are as close as we can be to mirroring the concept for the DUNE Table. It’s really exciting to us as a studio as it completely blows apart the conventional design brief.”

-Christopher Duffy, Founder of Duffy London.

Beginning a new era in design

Combining sustainable materials and production processes, the Dune Coffee Table is a revolutionary leap forward in furniture design. It marks an exciting beginning for our design studio, and inspires us to keep pushing boundaries while keeping sustainability and the environment in mind. By revolutionising furniture design with 3D printing, we can create pieces that are both artful, eco-friendly, and long-lasting.

The design world is shifting to a new horizon of eco-friendly production, and with the emergence of 3D printing in sand, we’re helping to usher in a new era of sustainable and concept-driven designs.

This is our commitment to creating furniture that embraces the beauty of nature , celebrates the strength of sustainable materials, and makes an effort to reduce our environmental impact. According to Chris, experiencing a permanent form emerge from millions of tiny particles was so inspiring that it made him want to explore even more ground-breaking materials and production methods.

“It’s just the beginning, We intend to offer special editions of some of our existing catalogue in this finish as we like it so much – imagine an Ab